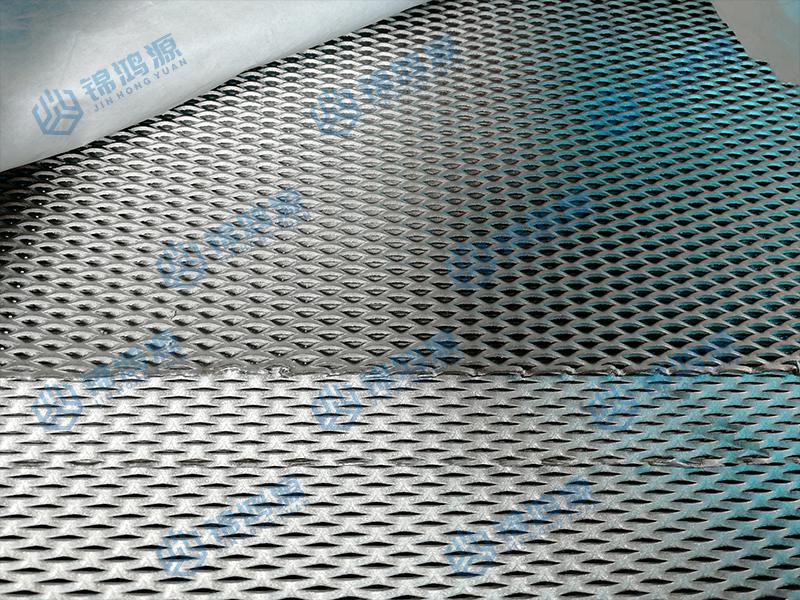

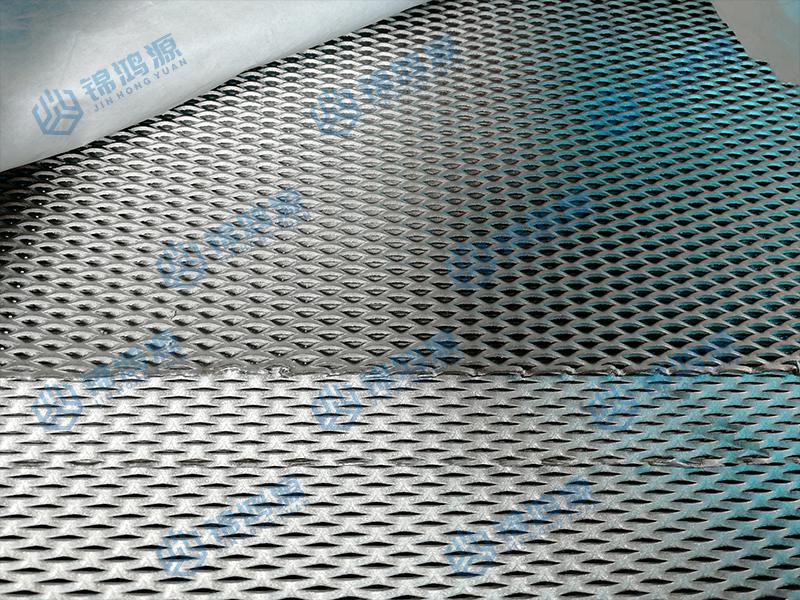

Titanium mesh classification

Plain weave titanium mesh: It is a common weaving method, characterized by the same density of warp and weft wire diameters.

Twill weave titanium mesh: The titanium wire used for diagonal weave titanium mesh has a slightly thicker diameter than the general plain weave wire, and the woven mesh has a greater strength. It is suitable for industries such as petroleum, chemical, chemical fiber, aerospace, etc., and has good acid resistance, alkali resistance, high temperature resistance, strong tensile strength, and wear resistance.

Titanium dense mesh: plain weave pure titanium dense mesh, diagonal weave pure titanium dense mesh Performance: It has the characteristics of stable and fine filtration performance. Usage: Used in industries such as aerospace, petroleum, and chemical engineering.

Materials: TA1, TA2, GR2, GR3, R50250, titanium alloy, etc

Material surface: 1. Black (with graphite emulsion coating on the surface) 2. Bright (without graphite emulsion coating)

Mesh size: 0.2 mesh to -400 mesh

purpose

Titanium mesh can be applied in industries such as high-temperature resistant filters, shipbuilding, military manufacturing, chemical filters, mechanical filters, electromagnetic shielding screens, seawater desalination filters, high-temperature electric furnace heat treatment support screens, petroleum filters, food processing, pharmaceutical filtration, etc.